T-Mag Mag Drive Pumps has a large inventory of the parts and accessories you need to minimize your down time and support any repair needed. T-Mag is one of the leaders in the fluid and flow handling industry and we stock the key parts and accessories you need for any Mag Drive Pump. Some accessories include hoses, gaskets, expansion joints, VFD’s and power monitors. T-Mag has made a name through numerous product innovations and patents that allow it to be one of the most reliable mag drive pumps in the market today. T-Mag is the answer for reliability and cost-effective pumping solutions.

Check out the AM Series or AMX Series Magnetic Drive Pumps!

Ethylene Flexijoint®

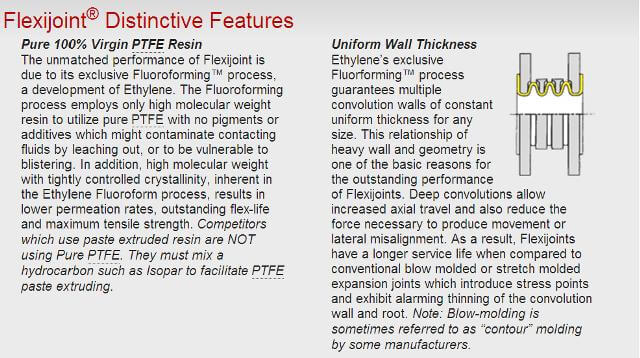

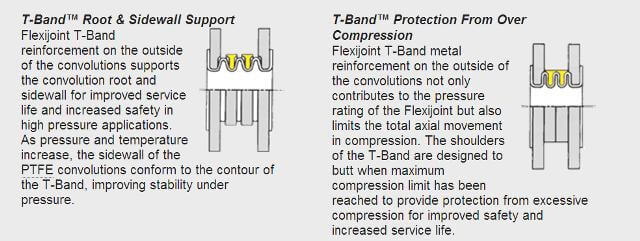

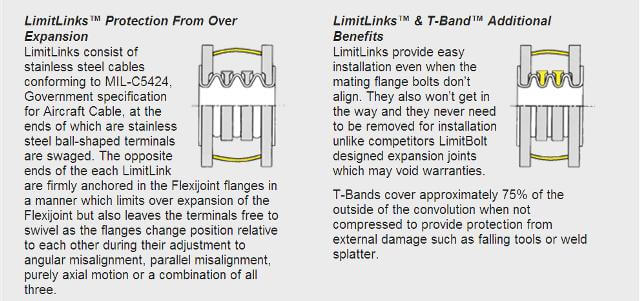

Ethylene Flexijoint PTFE expansion joints are flexible connectors and tremor barriers designed to compensate for misalignment, absorb expansion and contraction, and isolate vibration and shock in process piping, tanks and pumps. They also offer a low spring rate to protect stress sensitive FRP, glass or graphite equipment.

Flexijoints are available in sizes 1/2″ to 42″ and from 2 to 12 convolutions for maximum movements.

Flexijoint has almost universal chemical inertness, high and low temperature resistance, invulnerability to ozone and sunlight, outstanding flex life, and low acoustical impedance (sound dampening properties).

Pre-Cut Gasket Sheets are now available off the shelf. ANSI/ASME standard 150# class ring gaskets in both 1/8″, 1/16″ and 1/4″ thickness are immediately available. Other full faced and 300# class gaskets are available with very short lead times and can frequently be shipped on the same day as ordered. We have a large stock of INERTEX gasket products that are all available for purchase online.

- 100% expanded virgin PTFE

- pH range from 0 to 14

- Temperature range: -450°F to +600°F

- Pressure range, full vacuum to 3,000 PSI

- Extremely soft, excellent conformability

- Little creep or cold flow

- Low coefficient of friction (.02 like wet ice)

- FDA suitable (FDA 21 CRF 177.1550)

- No aging or hardening in service

Our distribution arm of the company carries many full lines of industrial hose. We stock and sell over 25 different hose, couplings, fittings, and fluid power lines and assemblies. We have a large stock of hoses that are all available for purchase online.

Emotron M20 - Reliable and Cost-Efficient Monitoring

The Emotron M20 shaft power monitor protects your pumps and other equipment against damage and downtime. Early warnings allow for preventive action, thus reducing maintenance costs and increasing reliability. Using the motor as a sensor also reduces installation costs.

The Emotron M20 shaft power monitor offers advanced multi-function monitoring thanks to two output relays, an analogue output and a display for load indication and parameter settings.

- Power Supply: 100-240 VAC / 380-500 VAC / 525-690 VAC

- Frequency: 50 Hz / 60 Hz

- Rated Current: up to 999 A (>100 A additional current transformer required)

- Protection: IP20

- Approvals: CE, UL, cUL

Unique shaft power monitoring: The Emotron M20 immediately detects over- and underload due to, for example, a pump running dry or a crusher jamming. A unique technique to calculate shaft power results in an accurate and reliable supervision across the whole load range.

High accuracy with scalable output signal: A unique feature offers high accuracy also in the event of very small load variations. An analogue current output signal can be used to scale the machine load to the actual working range. The signal can be used as an input to indicating instruments, controllers or PLCs.

Enter your settings in three seconds: The Emotron M20 uses a unique Auto set feature that allows four protection set points to be established in just three seconds. By pressing Auto set during normal operation, the warning and stop levels are calculated automatically on the basis of the actual motor load measured.

Low-cost installation and zero maintenance: Using the motor as a sensor eliminates the need for external sensors and extra cabling, and no holes need to be made in pipes. The result is increased reliability and reduced investment, installation and maintenance costs.

<div class="wp-block-contact-form-7-contact-form-selector">